GPM, PSI, and Choosing the Right Nozzle

Posted by American Pressure Inc on 24th Sep 2025

For construction professionals, keeping equipment, surfaces, and job sites clean is more than just aesthetics, it’s about safety, efficiency, and durability. Using a pressure washer incorrectly can waste water, damage surfaces, or slow down operations. Understanding PSI (pounds per square inch), GPM (gallons per minute), and selecting the right nozzle can dramatically improve cleaning performance while minimizing labor and water usage. This guide breaks down these essential concepts, helping contractors and industrial cleaners maximize their pressure washing efficiency.

Understanding PSI and GPM

PSI measures the water pressure produced by your pressure washer. High PSI allows you to remove tough substances like cement residue, mud, and oil more effectively, but excessive pressure can damage sensitive surfaces. GPM, on the other hand, measures the flow rate of water. While PSI determines how hard the water hits, GPM controls how much water is delivered to wash away debris. Together, PSI and GPM define the overall cleaning power of your pressure washer. For construction sites, the right combination of PSI and GPM ensures heavy-duty cleaning is efficient and safe, while the wrong mix can waste resources or create damage.

Selecting the Right Nozzle

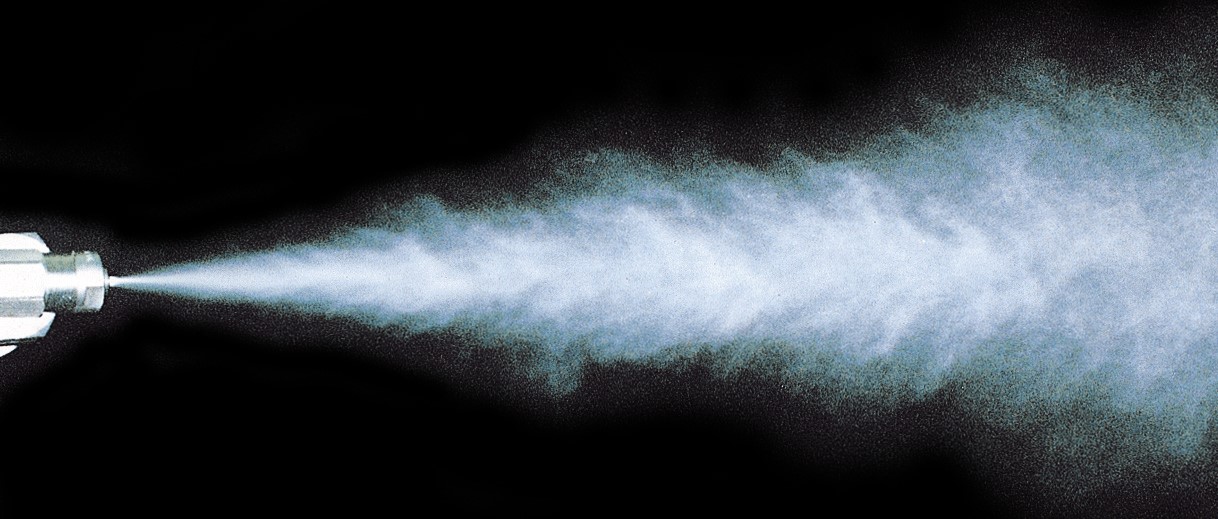

Nozzles control the spray angle and intensity of water, and choosing the correct one can make a major difference in cleaning effectiveness. Each nozzle type serves a unique purpose. A 0° nozzle provides a highly concentrated spray that can remove stubborn stains and hardened material, but it carries a higher risk of surface damage. A 15° nozzle is ideal for heavy-duty dirt, mud, and paint, offering strong, narrow spray coverage without being overly destructive. The 25° nozzle is versatile, making it suitable for general cleaning of machinery, concrete surfaces, and vehicles. A 40° nozzle provides a wide spray for light cleaning and rinsing, while soap nozzles are used for low-pressure detergent application. When selecting a nozzle, always consider the surface, the pressure you’re using, and the type of debris you’re cleaning. Contractors should keep a simple nozzle reference chart on site to quickly determine the most effective option.

Application in Construction Settings

Construction sites present unique cleaning challenges, and knowing how to apply the right PSI, GPM, and nozzle can save time and protect equipment. For heavy machinery, mud, grease, and concrete dust can accumulate rapidly. Using a 25° or 15° nozzle at moderate PSI and sufficient GPM allows these surfaces to be cleaned thoroughly without risking component damage. For surface preparation, such as cleaning concrete or asphalt before painting or sealing, it is important to use the correct nozzle to avoid leaving residue or damaging the substrate. Narrower angles may be required for stubborn spots, while wider sprays can cover larger areas efficiently. Debris and dust removal also benefits from a combination of moderate PSI and a versatile nozzle, ensuring dust and leftover materials are cleared without unnecessary water usage. When cleaning vehicles and trailers, rinsing from top to bottom with the right nozzle and pressure prevents streaks and makes post-construction cleanup more effective.

Safety should always be a priority. Contractors must wear protective gear, maintain a safe distance from surfaces, and ensure the work area is clear of other personnel when operating high-pressure equipment.

Maintenance and Best Practices

Proper maintenance ensures your pressure washer performs at peak efficiency and lasts longer. Regular cleaning of nozzles prevents clogs and maintains consistent spray patterns. Hoses, fittings, and pumps should be inspected before each use to catch leaks or wear early. Using a proper water supply prevents pump damage and reduces downtime. Storing equipment in a dry, sheltered location protects it from environmental damage, and following safety protocols, including gloves, goggles, and hearing protection, is essential for safe operation. Neglecting these steps can shorten the life of your equipment and reduce cleaning effectiveness.

Contractors often make common mistakes, such as using the wrong nozzle for a surface, combining too high PSI with low GPM, or ignoring maintenance schedules. By understanding the interplay of PSI, GPM, and nozzle selection, these mistakes can be avoided, saving time and resources.

Conclusion

For construction contractors, mastering GPM, PSI, and nozzle selection is essential for effective, safe, and efficient pressure washing. Correctly matching pressure, flow rate, and nozzle to the task ensures equipment and surfaces are cleaned properly, conserves water, and increases productivity on site. Assessing your current equipment and adapting your technique based on the cleaning task allows for better outcomes and fewer mistakes.

Frequently Asked Questions (FAQ)

- What PSI and GPM are best for cleaning construction equipment?

For most heavy machinery, a PSI range of 2500–3000 paired with a GPM of 4–6 is ideal. This combination provides enough force to remove mud, grease, and concrete dust without damaging sensitive components. Adjust nozzle selection depending on the specific surface or stubborn buildup. - How do I choose the right pressure washer nozzle for different tasks?

Start by identifying the surface and cleaning goal. Narrow-angle nozzles like 0° or 15° are best for tough, localized stains, while wider angles (25° or 40°) cover larger areas efficiently. Soap nozzles are ideal for detergent application and low-pressure cleaning. Keeping a simple reference chart on-site helps contractors select the right nozzle quickly. - Can I use the same PSI and nozzle for all surfaces?

No. Using too high PSI on delicate surfaces can cause damage, while too low PSI may leave debris behind. It’s important to adjust PSI, GPM, and nozzle type for each task — for example, concrete surfaces may handle higher pressure than painted surfaces or rubber tires. - How far should I hold the pressure washer from surfaces?

A general guideline is 2–3 feet from delicate surfaces and closer for heavy-duty cleaning spots. Maintaining the correct distance ensures effective cleaning while preventing damage. - How do I maintain my pressure washer and nozzles?

Regular maintenance includes cleaning nozzles, inspecting hoses and connections, using proper water supply, and storing equipment in a dry location. Following these practices extends the life of your equipment and ensures consistent cleaning performance.