Steam Nozzles are the best on Ice Dams.

Posted by American Pressure on 26th Mar 2022

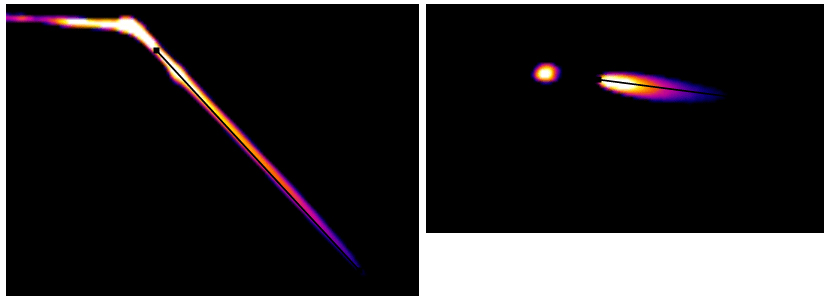

As temperature increases from the boiling point, the amount of energy that is used to change from water to vapor is increased, this leads to a changing of the mixture from very little vapor to all vapor (Dry Steam). Our testing has revealed that you need at least about 260-270°F to get enough vapor to change the behavior of the output (flashing to steam) so it is safe and gentle on surfaces and anything over about 300°F has too high a concentration of steam and can’t easily be directed to melt ice quickly. Heat Is concentrated and travels over 20” with our standard steam nozzle. The nozzle is designed to work with steam. And directs the energy and steam mixture to cut ice and for other tasks.

With a fan nozzle air quickly infuses and dissipates the energy. The temperature drops below 100°F in about a few inches with most heat lost in an inch and half. This leaves no ability to cut ice at a distance. However it makes for a larger steam cloud on the roof. Pressure washer nozzles have their place, but on a steam cleaner isn’t one of them.

The above pictures were taken with A Testo Thermal Imaging Camera on 2/12/2019. Both were on an Arctic Steamer operating at about 280°F. The system pressure on the steam nozzle was 300 PSI, on the fan nozzle the pressure was 800 psi, using a 25° Angle. BOTH WHERE THE SAME TEMPERATURE.

Left is a Fahrenheit Scale for the thermal image color Scheme. White is over 150°F and Black is under 105°F

Ice dam removal