Understanding Pressure Washer Unloaders: The Unsung Hero of Your System

Posted by American Pressure Inc on 9th Oct 2025

What Is an Unloader Valve?

The unloader valve is one of the most important yet least understood parts of any pressure washer system. It controls the flow of water through your pump by redirecting it back to the inlet when the trigger gun is released.

In simple terms, the unloader keeps your system safe and prevents excessive pressure buildup when you’re not spraying.

Without a working unloader:

-

Pressure can build to unsafe levels

-

Pumps and hoses can wear out faster

-

The entire system can fail under stress

Shop Pressure Washer Unloaders →

How an Unloader Works

When you squeeze the trigger on your spray gun, water flows through the nozzle at full pressure.

When you release the trigger, the unloader valve instantly redirects that water flow back to the pump inlet or into a bypass line.

This process:

-

Prevents over-pressurization

-

Reduces wear on your pump and seals

-

Keeps your system running smoothly between trigger pulls

You can think of the unloader as your system’s safety valve and pressure regulator working together.

Signs Your Unloader May Need Service

Even the toughest unloaders wear down over time, especially in high-use or high-heat systems.

Watch for these signs:

-

Inconsistent or spiking pressure readings

-

Water leaking near the unloader body

-

The motor or engine bogs down when you release the trigger

-

The machine fails to bypass or “load up” properly

If you notice any of these issues, stop using the washer until it’s inspected. Running a bad unloader can cause serious pump damage.

Schedule a Service Appointment →

Types of Unloaders

At American Pressure Inc, we service and stock several types of unloaders depending on system design:

Trapped Pressure Unloaders

Hold pressure in the hose until you pull the trigger again. Common on most portable pressure washers.

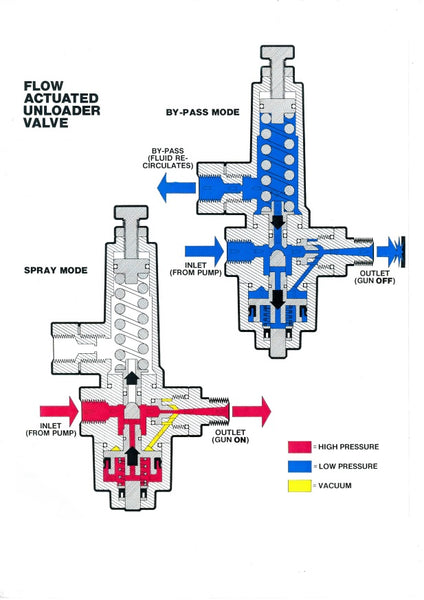

Flow Actuated Unloaders

React to changes in water flow, offering smoother operation and less stress on components. Often found in industrial systems.

If you’re not sure which one your system uses, our team can help identify it and recommend the best fit for your setup.

Maintaining Your Unloader

Regular inspection and cleaning will keep your unloader working longer.

Here’s how to maintain it:

-

Keep fittings tight and check for leaks

-

Relieve system pressure before adjusting settings

-

Always follow manufacturer recommendations for PSI adjustment

Incorrect adjustments can reduce cleaning power or shorten your pump’s life.

When to Replace or Repair

Some unloaders can be rebuilt if only small parts like springs or seals are worn.

But if you notice corrosion, heavy wear, or cracks, it’s best to replace the unit entirely.

We carry a full range of OEM and compatible unloaders for commercial and industrial systems.

Browse Unloaders and Replacement Parts →

Get Expert Help from American Pressure Inc

From unloaders and pumps

to hoses, nozzles, and full wash bay systems

American Pressure Inc is your one-stop shop for everything pressure-related.

Need help diagnosing a pressure issue?

Contact our service team or visit americanpressureinc.com to find the right unloader for your system.